Video: Niagara Cutter Universal Drill Demonstration | SECO TOOLS

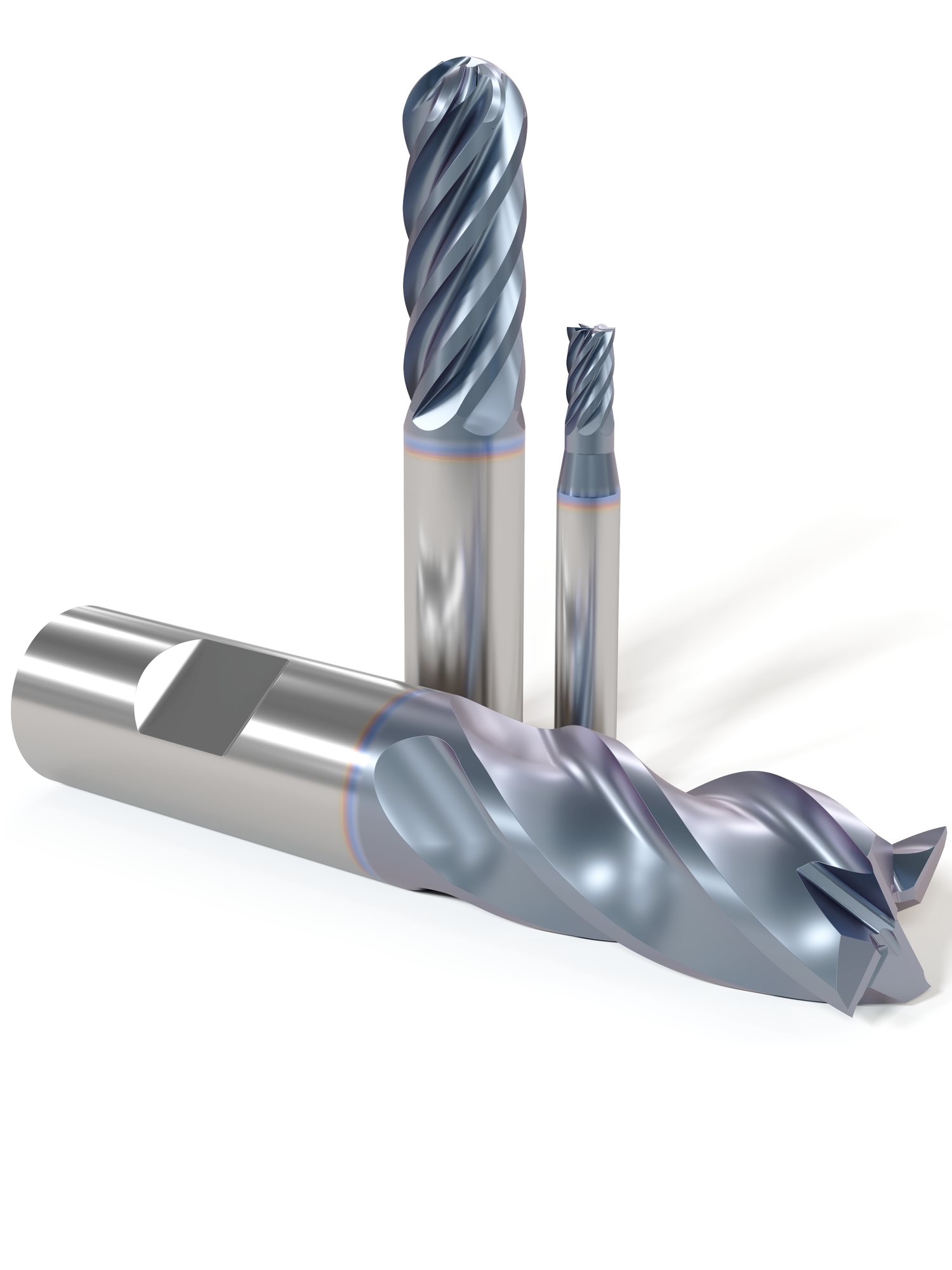

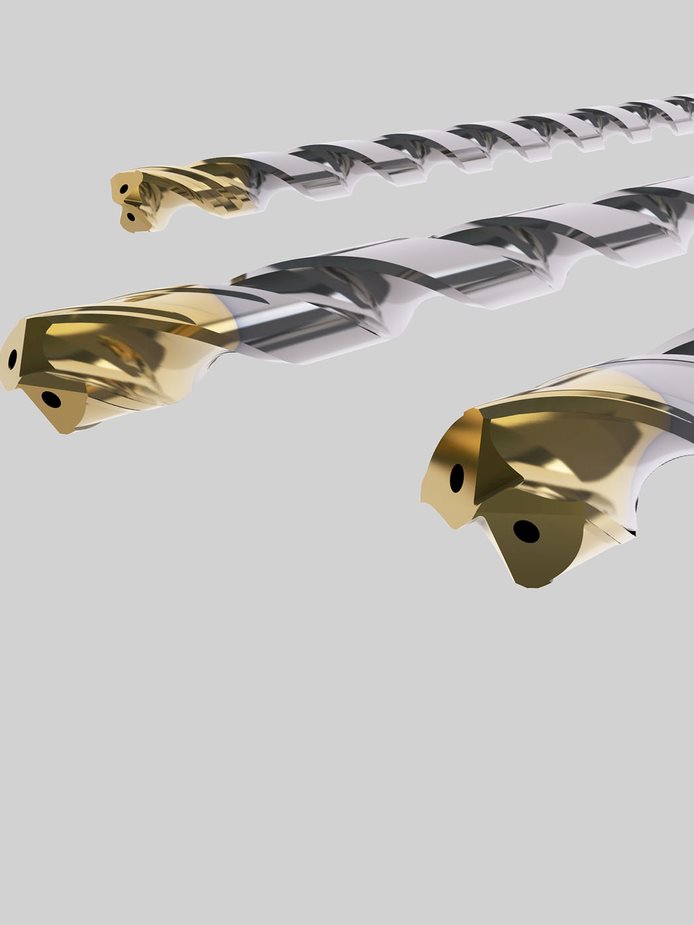

Developed with optimum performance and value in mind, the new Universal Drill from Niagara Cutter combines a special multi-purpose geometry with advanced coating technology to provide reliable, predictable tool life and the lowest cost per hole, especially in high-volume production environments.

This solid-carbide drill's rigid four-facet point geometry provides excellent centering capability, maintains an IT8/9 hole tolerance and is easy to regrind. A polished AlCrN coating gives the drill high abrasion resistance, toughness and good chip evacuation capabilities. Well suited for holemaking applications across all industry segments and a wide scope of workpiece materials, including steels, stainless steels and cast irons, the versatility of the Universal Drill helps reduce required tooling inventories.

Available drill diameter sizes range from 3 mm to 20 mm with increments of 0.1 mm. For efficient chip evacuation, the 5 x D and 3 x D length drills with cylindrical shanks offer the option of through-tool coolant capability. All Universal Drills are compatible with Seco shrinkfit holders, hydraulic chucks and high-precision collet chucks.

Related content

Video: Niagara Cutter Universal Drill Demonstration | SECO TOOLS

Octomill 06: Explanation and comparison of the system design

Octomill 06: Insert Handling

Video: SLIM DISC THREAD MILLING APPLICATION

Niagara Cutter Universal Drill Product Introduction

Video: Niagara Cutter AN230 & AN335 High-Velocity Solid End Mill for Aluminum

Video: Multi Flute Range Addition

Video: Niagara Cutter NTM100 Threadmill

Video: Optimized Roughing 17 4 PH Stainless Steel Dry

Video: Optimized Roughing 17 4 PH Stainless Steel Dry

Video: Niagara Cutter ELITE Series Multi Flute S638

Video: Niagara Cutter's SN200R, SN400R and SN500R

Video: Niagara Cutter NTM100 Threadmill

Video: Shed light on your entire business with Global Tool Deterioration Analysis I Seco Tools

Video: Getting Technical - Profitable small batches, can efficiency and sustainability coexist?

Video: Deep Hole Drilling with the Seco X-Tra Long Solid Carbide Drill | Seco Tools

Video: Beyond recycling: Seco's vision for circular manufacturing | Seco Tools

Video: Optimized machining data for small batch production

Video: Machining strategies for small batches of high-quality parts

Video: Connect CAM programming, competency and capacity with Seco Engineering Services I Seco Tools

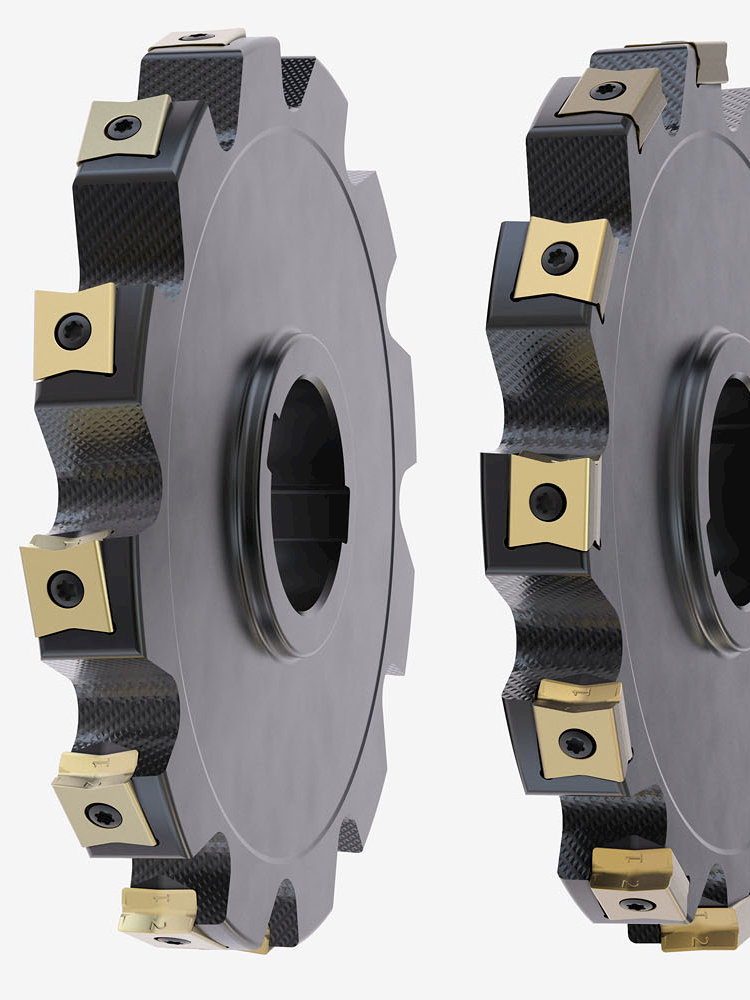

Machine two sides of a part securely with Seco disc milling cutter system | Seco Tools