Video: Reduce Machine Downtime For High Cost Savings With Double Turbo

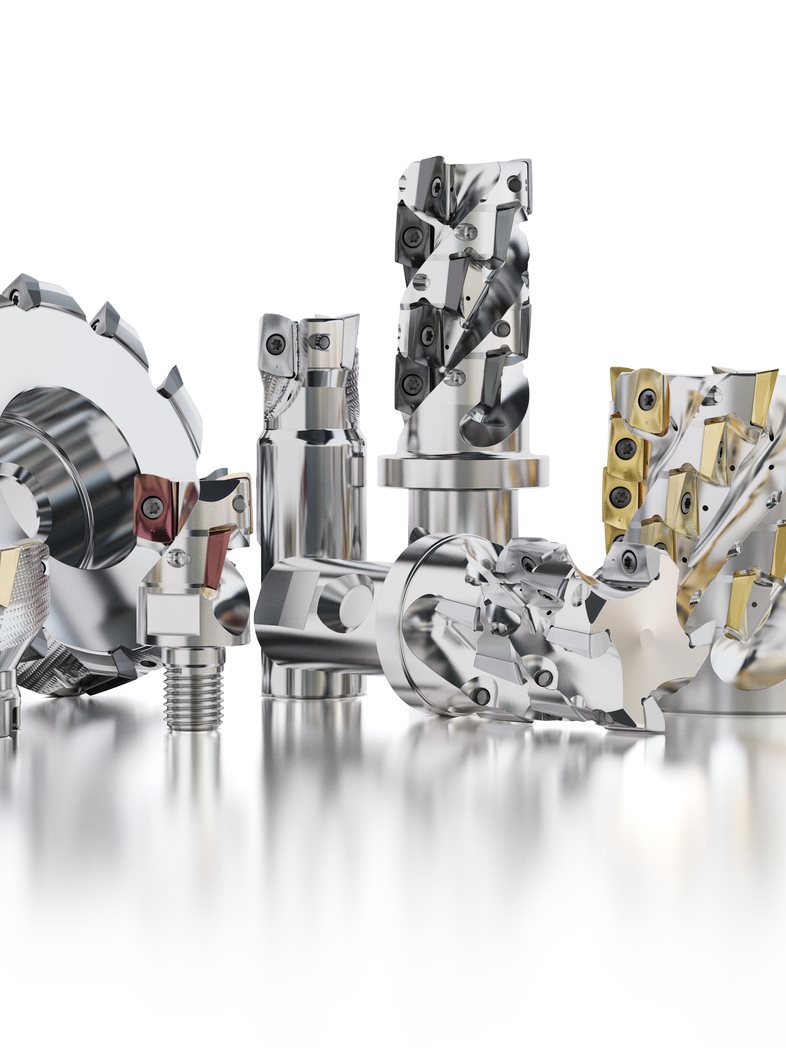

When milling in steel, stainless steel, and titanium, it is now possible shorten or completely eliminate your finishing time with the Double Turbo square shoulder mill from Seco Tools. With these double-sided inserts, you are able to increase your productivity, reduce downtime, and ultimately increase costs.HOMERelated content

Video: Reduce Machine Downtime For High Cost Savings With Double Turbo

Octomill 06: Explanation and comparison of the system design

Octomill 06: Insert Handling

DOUBLE TURBO 16

Seco Tools Introduces Double Turbo Square Shoulder Mills and Inserts

Seco Tools adds Turbo 16 Square Shoulder Cutter to the industry-leading Turbo Portfolio

Video: SLIM DISC THREAD MILLING APPLICATION

Video: Double Turbo Milling Applications of Steel, Cast Iron, & Stainless Steel

Video: Double Turbo Square Shoulder Mill With Double-Sided Inserts

Video: Product Introduction Of Double Turbo Shoulder Mill

Video: Double Turbo's Double-Sided Edges Increase Productivity

Video: Shed light on your entire business with Global Tool Deterioration Analysis I Seco Tools

Video: Getting Technical - Profitable small batches, can efficiency and sustainability coexist?

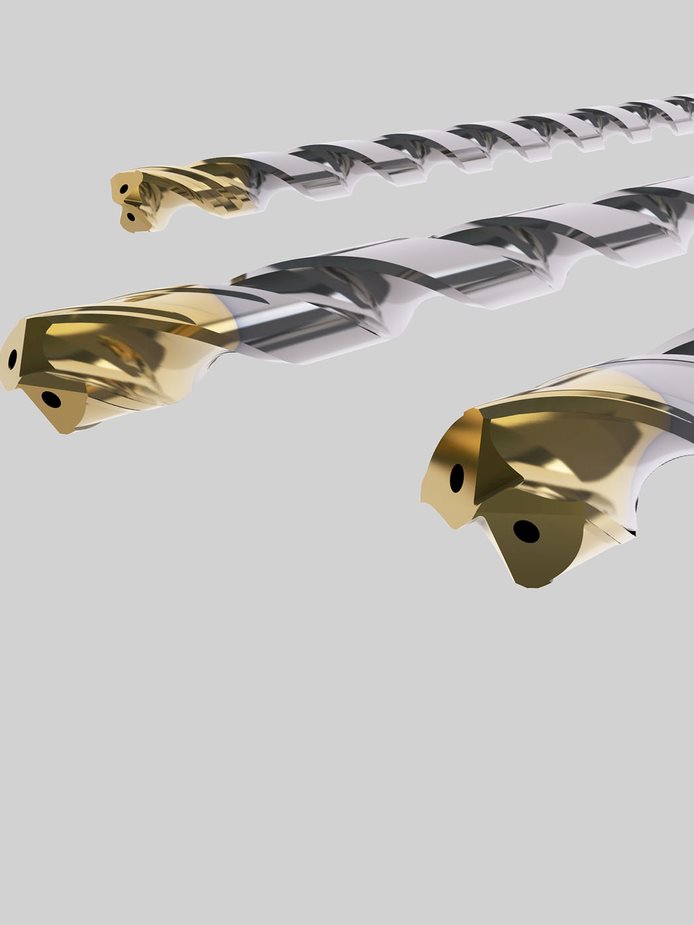

Video: Deep Hole Drilling with the Seco X-Tra Long Solid Carbide Drill | Seco Tools

Video: Beyond recycling: Seco's vision for circular manufacturing | Seco Tools

Video: Optimized machining data for small batch production

Video: Machining strategies for small batches of high-quality parts

Video: Connect CAM programming, competency and capacity with Seco Engineering Services I Seco Tools

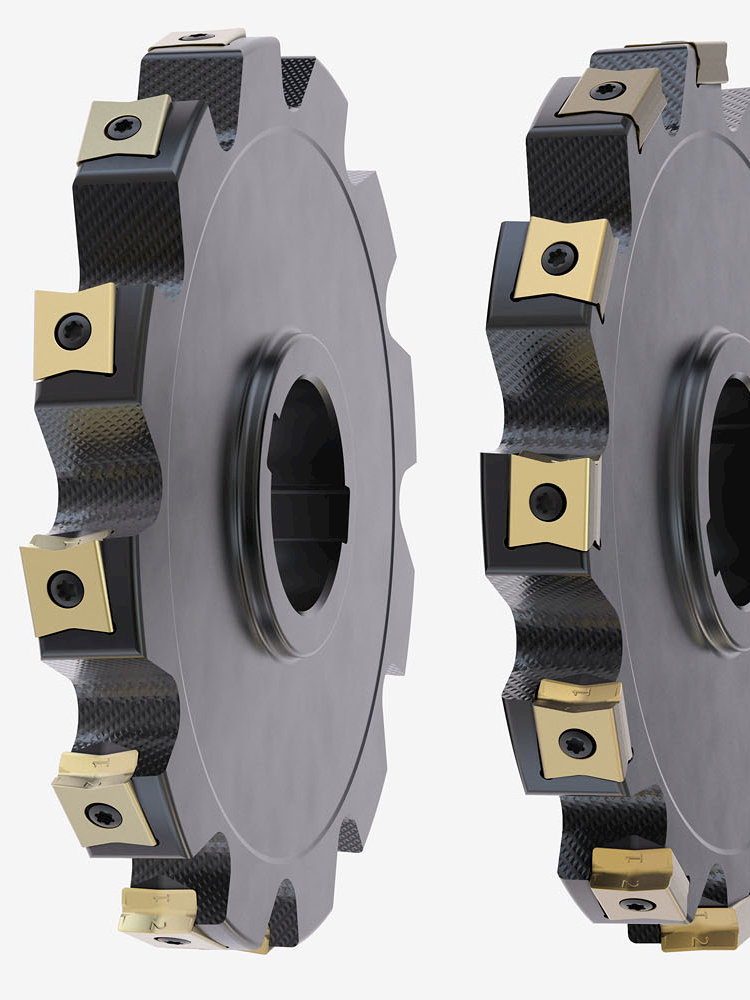

Machine two sides of a part securely with Seco disc milling cutter system | Seco Tools

Video: Advances in superalloy machinability

Video: Fostering an Inclusive Workplace Where Everyone Thrives | Seco Tools